Become a Patron to see this content

To view this content, you must be a member of Justin's Patreon at $1 or more

Already a qualifying Patreon member? Refresh to access this content.

RF elements talks about migration to horns.

Some random shots from the TowerOne Inc booth at WISPAMERICA 2019 in Cincinnati.

Nick from Toweroneinc talks about the new Rope Cannon for use on a rope. This device makes storing your rope at the end of the day a quick job

•Handles all ropes up to 20mm (3/4 inch) diameter

• Works wet, dry or dirty

• Load ropes midline or from end

• Great for measuring: 1 Crank = 3ft Rope

Recently we installed a PTP 550 link for a client. This is a connectorized version with 2-foot dishes on it for a four-mile link. Overkill you say, but the idea is the dishes make up the gain and not transmitter power. A much cleaner signal can be achieved which falls within the FCC guidelines for total EIRP.

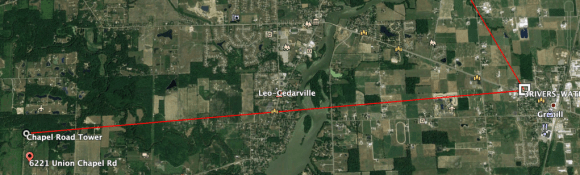

So let’s get to it. Our first image is out path. This link had clear line of sight from a 150-foot foot water tower to a 240-foot tower.

After getting out of the cold we let things burn in for a few days. This is what an initial spectrum analysis looked like.

As you can see the RSSI was within 2 DB, which isn’t terrible. However, due to interference, the MCS rates are markedly different, which is what results in the big differences in speed. Please note this is only with one radio enabled and on a 20mhz channel. We fully expect bigger speeds once we up channel sizes and enable the second radio.

You must be logged in to post a comment.